King’s College London (King's) is one of the most long-established and prestigious universities in England, consistently garnering top rankings across the United Kingdom and the world.

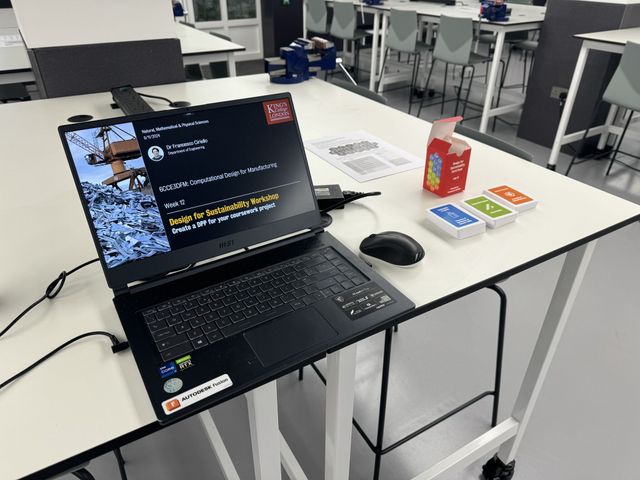

Under the guidance of Dr Francesco Ciriello, Senior Lecturer in Engineering Education, and an expert in project-based learning and computational engineering design, students now have an immersive course that equips them with the tools to create and communicate sustainable product attributes using DPPs.

Founded in 1829, the institution offers highly regarded programmes in law, medicine, management, the arts, and more. In fact, the university’s Department of Engineering is one of the leading engineering schools in the U.K., offering a variety of degree programmes with innovative research opportunities, cutting-edge facilities, and strong connections with industry.

Training next-generation product leaders

Keeping students on the leading-edge of real-world engineering topics is always top-of-mind for the Engineering Department. And for Dr Ciriello, Senior Lecturer in Engineering Education at King’s College, training students on sustainability is at the forefront of his curriculum.

Immersive course in Computational Design for Manufacturing

Given the significance of eco-design – for future generations and in light of new regulations – our course’s Design for Sustainability workshop helps students discuss broad sustainability topics to rapidly develop strategies they could apply to their diverse and open-ended projects.

“Our Design for Manufacturing course leverages new computational ways of thinking, which combined with critical making skills, helps students design commercial products and manage complex trade-offs. Students journey through the entire design & make process, applying AI-assisted technologies to design, iterate, and build prototype products, taking their ideas from conception to implementation and manufacture,” Ciriello said.

“Given the significance of eco-design – for future generations and in light of new regulations – our course’s Design for Sustainability workshop helps students discuss broad sustainability topics to rapidly develop strategies they could apply to their diverse and open-ended projects.”

Forward-thinking instructional design

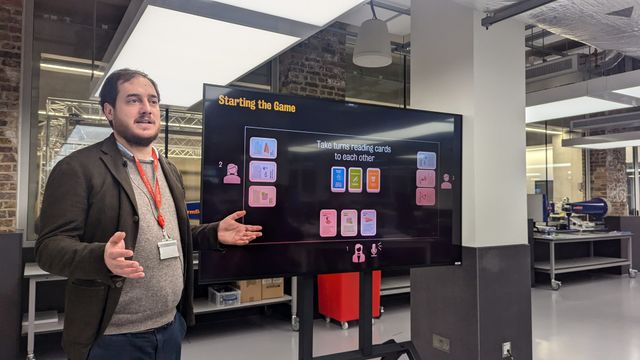

Not only does the course address cutting-edge topics, but Ciriello is forward-thinking in his instructional design – incorporating gamification, rapid prototyping, and generative ideation into the students’ learning process.

Applying computational engineering to real-world projects

Throughout the course, students applied engineering principles to real-world projects. In the first week, participants brainstormed product ideas to design; analysed pros and cons; and conducted extensive background research on existing standards, product features, and potential improvements.

Iterating on product designs

From there, in subsequent weeks, students worked through an iterative design process, selecting a product to build, while evaluating engineering constraints, materials choice, load factors, and other elements. Participants solicited feedback from peers and mentors on their computer-assisted drawing (CAD) designs and ran their schematics through engineering simulations to test their viability.

Rapid prototyping in state-of-the-art labs

Then, they built prototypes of their designs in the Engineering Department’s 3000-square-metre, state-of-the-art lab facilities, which include maker spaces with 3D printers, laser cutting, casting and moulding machines, and a variety of other manufacturing equipment.

Focusing on sustainability using innovative instructional design

On Week 6 of the course, students participated in a Design for Manufacturing workshop, where Ciriello applied innovative instructional design to engage participants with sustainability topics. Using generative artificial intelligence, Ciriello distilled key concepts from the European Union’s new Ecodesign for Sustainable Products Regulation (ESPR) into a colour-printed card deck.

A gamified approach to learning

Then, students engaged in a gamified approach to learning, drawing cards from the deck, and applying sustainability interventions to improve their products. The cards contained challenges for students to work through, such as:

- Implementing a design strategy focused on creating products with minimal material usage and a modular architecture, where components can be easily disassembled and reused or recycled.

- Utilizing 3D printing to create spare parts or components that can be produced on demand, encouraging reuse of existing products by providing the means to replace worn or damaged parts.

- Choosing steel grades that are widely accepted in recycling programmes, such as carbon steel and stainless steel, which can be melted down and repurposed with minimal quality loss.

- Designing moulds and tooling that facilitate easy disassembly and reassembly of parts, allowing for quick repairs in injection-moulded products and reducing the barriers to maintaining product functionality.

Creating Digital Product Passports to showcase product data

Because Digital Product Passports (DPPs) are a key part of the ESPR legislation, a core element of the workshop was to have students create DPPs to communicate the product details that they had spent weeks working on.

Ciriello is an expert in project-based learning and computational engineering design – having researched and lectured widely on the topics – and as a result, he wanted to infuse generative AI into the learning activities for Digital Product Passports.

Accelerating DPP creation with generative AI

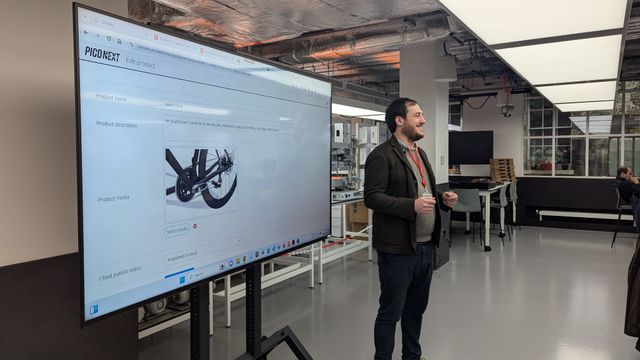

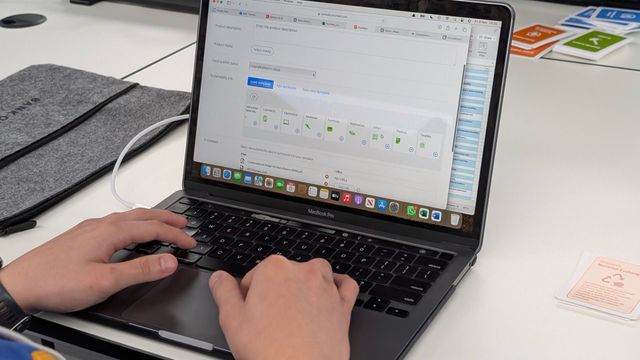

Using PicoNext, students uploaded their raw data and notes about their product designs into the PicoNext AI Assistant. Then, they selected a DPP template that aligns with their product category and the reporting requirements of the ESPR regulation – including product attributes like raw materials composition, recyclability, presence of substances of concern, durability and more.

The PicoNext AI Assistant analysed the data, and generated summary paragraphs for each Digital Product Passport category, which students could further edit and revise. Then, students published their DPPs into concisely formatted landing pages to share with colleagues and include in their final coursework submission. Because the ESPR regulation includes the concept of a “data carrier” – or an easy way for consumers to access the DPP data – students could also download a QR code that provides a direct link to their formatted DPP landing page.

Creating Digital Product Passports is an important way to communicate and critique its return-on-investment (ROI), and we wanted our students to be well-versed in best practices to do so – especially as new regulations roll out over the next months and years.

Using generative AI in PicoNext, we could leverage a small quantity of product attributes in a data lakehouse to create an attractive DPP customer-facing landing page, in no time at all.

“Creating Digital Product Passports is an important way to communicate and critique its return-on-investment (ROI), and we wanted our students to be well-versed in best practices to do so – especially as new regulations roll out over the next months and years,” said Ciriello. “Using generative AI in PicoNext, we could leverage a small quantity of product attributes in a data lakehouse to create an attractive DPP customer-facing landing page, in no time at all.”

Driving real-world impact with evidence-based engineering

For Ciriello, helping students incorporate eco-design and Digital Product Passports is more than just helping them to be compliant with regulations in Europe and beyond – it’s helping them make evidence-based engineering decisions that enhance sustainability.

As students grapple with product engineering tradeoffs – in raw materials, durability, repairability, recycling and more – through a lens of eco-design, they become better equipped to create more sustainable products in whatever organisation they end up working for.

And because their best-in-class education spans topics from artificial intelligence and digital twins to rapid prototyping and Digital Product Passports, King’s College engineering students are not only in demand by future-looking employers, but ready to drive real-world impact too.